Best Chinese Factories For UK Sliding Bearing Buyers

Why UK Buyers Source Sliding Bearings from China

As the UK industrial landscape continues to expand across sectors like manufacturing, renewable energy, automotive, and construction, demand for high-performance sliding bearings has grown significantly. UK buyers increasingly look to Chinese factories as reliable and cost-effective sources for engineered sliding bearings, thanks to China’s advanced manufacturing ecosystem, competitive pricing, and export prowess.

In this article, we explore the best Chinese factories that UK sliding bearing buyers should consider, key factors to evaluate when sourcing, and why partnering with trusted suppliers like www.cnepen.com delivers both quality and long-term value.

Why UK Buyers Source Sliding Bearings from China

Before we list the top factories, let’s look at why UK buyers consistently turn to China for sliding bearings:

1. Competitive Manufacturing Costs

China’s industrial production infrastructure enables large-scale manufacturing with lower operational costs than many Western countries. This translates to competitively priced sliding bearings without sacrificing performance.

2. Broad Product Range

Leading Chinese factories produce not only standard plain bearings and bushings but also advanced materials such as:

Composite maintenance-free bearings

High-temperature and corrosion-resistant designs

Bi-metallic and self-lubricating solutions

👉 Browse CNEPEN’s full range of sliding bearings

https://www.cnepen.com/sliding-bearings

3. Customization Capabilities

Chinese OEM manufacturers often offer tailored bearing designs, allowing UK buyers to specify custom sizes, surface finishes, and performance requirements to match specific applications.

4. Export Experience and Logistics

Many Chinese factories have strong export experience to Europe and the UK, reducing lead times and simplifying import processes.

Top Chinese Sliding Bearing Factories UK Buyers Should Consider

Here are some of the best Chinese factories worth considering when sourcing sliding bearings:

🏭 1. CNEPEN

Why UK Buyers Choose CNEPEN:

CNEPEN stands out as a professional sliding bearing manufacturer focused on engineered solutions for high-demand industrial applications. Their expertise covers everything from standard plain bushings to advanced composite bearing designs suitable for harsh environments and severe load conditions.

Key Strengths:

✔ Strong quality control and material traceability

✔ Composite, maintenance-free, and high-temperature bearings

✔ Full global export support

✔ Excellent technical consultation

👉 Explore CNEPEN sliding bearing products

https://www.cnepen.com/sliding-bearings

🏭 2. Factory with Composite Maintenance-Free Bearing Focus

What They Offer:

Some Chinese factories specialize in composite materials and self-lubricating bushings that perform reliably without relubrication — a significant advantage for UK buyers in sectors like rail, automotive, and remote machinery.

Product Highlights:

Low friction, high wear resistance

Ideal for applications where access for maintenance is limited

👉 Maintenance-free sliding bearings from CNEPEN

https://www.cnepen.com/maintenance-free-bushings

3. High-Temperature & Corrosion-Resistant Bearing Manufacturers

Industry Relevance:

Factories that produce sliding bearings capable of resisting elevated temperatures and corrosive environments are valuable for UK industries, including energy, chemical processing, and offshore applications.

Performance Attributes:

Thermal stability at elevated temperatures

Enhanced corrosion resistance

Long service life in harsh conditions

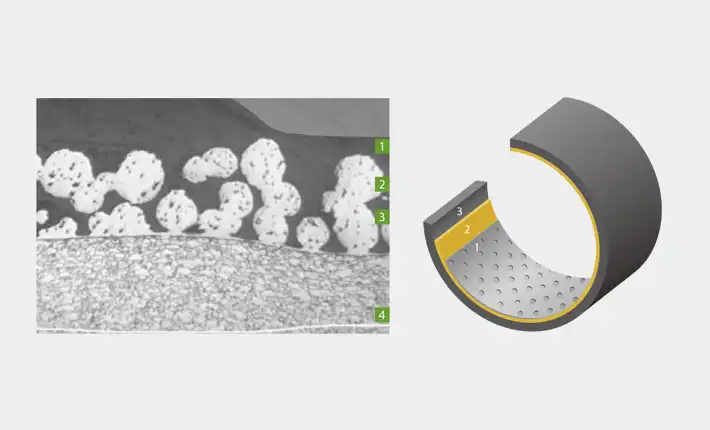

4. Heavy-Duty Tri layer-Metallic Bearing Producers

Application Advantage:

Some factories specialize in tri layer metallic sliding bushings, which combine steel backing with a wear-resistant overlay for excellent load capacity — vital for heavy machinery, construction, and mining equipment.

👉 Tri layer metallic bushings and heavy-duty solutions

https://www.cnepen.com/bi-metallic-bushings

Tips for UK Buyers When Sourcing from China

To ensure a robust procurement process:

✔ Ask for samples before a full order

✔ Confirm material specifications and testing standards

✔ Validate tolerance and fitting requirements

✔ Compare total landed cost (bearing price + shipping + duties)

These steps reduce risk and ensure components match UK operational expectations.

Conclusion

China remains one of the most strategic and cost-effective sourcing regions for sliding bearings for UK industrial buyers. The country’s manufacturing strength, combined with export expertise and customization capabilities, make it a prime choice.

However, choosing the right supplier is critical. Reputable factories like CNEPEN combine product quality, engineering support, and global delivery experience, helping UK buyers minimize risk and maximize bearing performance.

FAQ

What distinguishes plain bearings from ball bearings in industrial applications?

Plain bearings work by moving surfaces that are oiled against each other, while ball bearings use rolling elements to lower friction. When there is a lot of load, plain bearings work better than ball bearings, and they can handle errors better. Because they are smaller and cost less to buy at first, they are better for heavy tools and building equipment.

How do I select appropriate bearing materials for specific operating conditions?

The type of load, working temperature, chemical surroundings, and lubrication factors all affect the choice of material. Bronze metals work well in high-load situations where there is good lubrication, while composite materials work best when there is little or no lubrication. PTFE-lined bearings work well in places where corrosion is a problem, and metal-plastic alloys are very good at resisting wear in tough situations.

What are typical lead times for custom bearing orders from Chinese factories?

Standard store items usually ship in one to two weeks, but special bearings can take anywhere from three to six weeks, based on how complicated they are. Orders that need to be processed quickly may be able to be done so. Lead times depend on the number of items ordered, how complicated the specifications are, and how busy the factory is right now. To cut down on shipping times, established sellers often keep stock of popular configurations.

Partner with Epen for Your Plain Bearing Requirements

Connect with Epen's experienced team of bearing experts who know the specific needs of UK industrial uses to speed up the buying process. Our large catalog of plain bearings includes metal-plastic hybrid, bimetal, and sliding bearing options that are made to work in tough situations. With decades of experience making things and a dedication to quality, we provide solid parts that improve the performance of tools while lowering the cost of repairs.

Get in touch with our expert team at epen@cnepen.cn to talk about your unique bearing needs and get suggestions that are made just for you. We accept questions about both standard catalog items and custom specs. Our prices are reasonable, and you can choose the amount of items you want to buy based on your procurement goals. Find out how our skills as a plain bearings provider can help your business succeed by providing high-quality products and quick responses to customer needs.

References

Industrial Bearing Technology and Applications in Modern Manufacturing Systems, British Standards Institution, 2023.

Global Plain Bearing Market Analysis: Manufacturing Trends and Supplier Evaluation Criteria, UK Industrial Components Association, 2023.

Quality Management Systems in International Bearing Manufacturing: A Comprehensive Guide for UK Procurement Professionals, Institution of Mechanical Engineers, 2022.

Supply Chain Risk Management in Industrial Component Sourcing: Best Practices for UK Manufacturers, Chartered Institute of Procurement & Supply, 2023.

Advanced Materials in Plain Bearing Applications: Performance Characteristics and Selection Guidelines, Materials Science Society of UK, 2023.

International Supplier Evaluation Framework for Precision Industrial Components, British Engineering Manufacturers Association, 2022.

Dr. Eleanor "Ellie" Penn

Dr. Eleanor "Ellie" Penn is our Senior Tribology Specialist at Epen, where she bridges the gap between deep material science and real-world engineering challenges. With over 15 years of experience in the field of sliding bearings and self-lubricating materials, she possesses a passion for solving the most complex problems of friction, wear, and maintenance. Ellie holds a Ph.D. in Mechanical Engineering with a focus on tribology. Her mission is to empower engineers and maintenance professionals with practical knowledge and best practices that extend equipment life, reduce downtime, and drive innovation. When she's not in the lab or writing, you can find her volunteering at STEM workshops to inspire the next generation of engineers. Areas of Expertise: Sliding Bearing Design, Material Selection, Failure Analysis, Preventive Maintenance, Application Engineering.

Contact to EPEN Bearing

If you have any questions please do not hesitate to call or write us.

Recommended Blog