In industrial applications, sliding bearings play a critical role in ensuring the smooth operation of machinery and equipment. However, like all components, sliding bearings can wear out over time. One of the most effective ways to monitor their condition and prevent unexpected failures is by analyzing wear particles. This method offers valuable insights into the health of the bearings and helps diagnose potential problems before they lead to costly breakdowns.

In this article, we’ll explore how to analyze wear particles in sliding bearings and how this technique can be used to diagnose equipment conditions. We’ll also look at the tools and methods involved in this analysis and how it can be integrated into your maintenance strategy.

What Are Wear Particles in Sliding Bearings?

Wear particles are tiny fragments or debris that are generated when the sliding surfaces of bearings experience friction and wear. These particles are typically made of the materials that the bearing is composed of (such as steel, bronze, or composite materials) and can vary in size, shape, and composition depending on the severity of wear and the operational conditions.

The analysis of these particles can provide a wealth of information regarding the type and extent of wear that is occurring inside the bearing. For instance, large or irregularly shaped particles may indicate significant friction or abrasive wear, while smaller, metallic particles could suggest the presence of corrosion.

Why Analyzing Wear Particles is Crucial

Early Detection of Problems

Wear particle analysis can detect early signs of bearing wear, such as surface damage, lubrication issues, or contamination. This proactive approach allows maintenance teams to address potential failures before they escalate into serious issues.

Identify Root Causes

By understanding the type of wear particles, you can identify the root cause of bearing degradation. Whether it’s inadequate lubrication, contamination, or misalignment, particle analysis helps pinpoint the underlying issue.

Monitor Bearing Performance

Regular analysis of wear particles can provide ongoing insights into the performance of sliding bearings. This helps you track how the bearings are holding up over time and whether they require adjustment or replacement.

Improve Maintenance Planning

Wear particle analysis helps in building a more effective and targeted maintenance strategy. By identifying trends and patterns in the particles over time, maintenance schedules can be optimized, and spare parts can be ordered in advance, reducing downtime.

How to Analyze Wear Particles in Sliding Bearings?

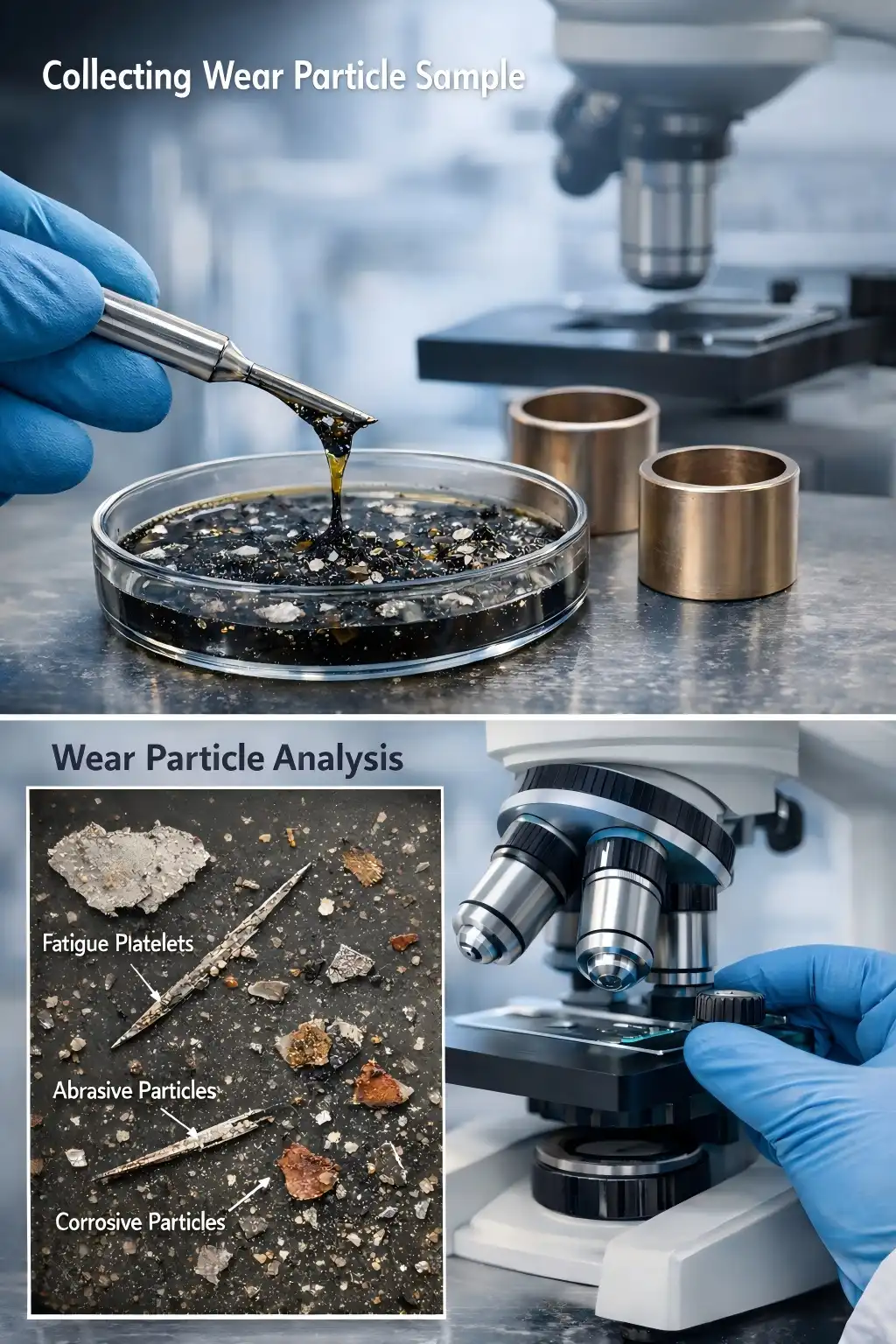

Sampling the Wear Particles

The first step in the analysis is to collect a sample of the wear particles. This can be done by using a magnetic particle trap, filtration system, or oil sample. Ensure that the sample is taken from a point where particles are likely to accumulate, such as the bearing housing or oil filter.

Visual Inspection and Size Analysis

Once the sample is collected, the next step is to perform a visual inspection. Using a microscope or magnifying tool, technicians can examine the shape, size, and color of the particles. The morphology of the particles provides crucial information about the wear mechanism. For example:

Flat or disc-shaped particles: Indicate sliding wear or surface fatigue.

Long, needle-like particles: Suggest abrasive wear or contamination.

Metallic particles: Indicate corrosion or wear of the bearing material.

Elemental Analysis

Advanced techniques such as X-ray fluorescence (XRF) or energy-dispersive X-ray spectroscopy (EDS) can be used to perform elemental analysis of the particles. This helps to identify the exact materials that the particles are made from, which can give more insight into the specific bearing components that are being worn away.

Comparative Analysis

By comparing wear particles from different periods, you can track the progress of wear and assess whether the bearing condition is improving or worsening. This comparison helps maintenance teams determine if the wear rate is within acceptable limits or if immediate action is needed.

Oil Wear Particle Count

Another method is to count the number of wear particles in the oil sample. An elevated number of particles may suggest that the bearing is deteriorating. Additionally, particle count analysis can be used to monitor the effectiveness of lubrication and detect contamination levels in the system.

Tools for Wear Particle Analysis

There are several tools and technologies available for wear particle analysis, depending on the level of detail required:

Wear Debris Sensors: These sensors are integrated into the bearing or lubricant system and continuously monitor the presence and quantity of wear particles.

Magnetic Particle Traps: Used to collect magnetic wear particles from the lubricant. Ideal for ferrous bearings.

Microscopes: High-powered microscopes are essential for inspecting the size and morphology of wear particles.

Spectrometers: Used for precise elemental analysis, helping to determine the composition of the particles.

At CNEPEN Bearings, we offer a range of products that can help with wear particle analysis, including advanced oil filtration systems designed to improve the efficiency of your maintenance strategy.

How This Helps Diagnose Equipment Condition

The wear particles provide critical insights into the overall condition of the equipment. By identifying the type of particles and their quantity, technicians can:

Predict failure points: Predict when a bearing is likely to fail or require replacement based on wear trends.

Optimize lubrication: Improve the lubrication strategy by identifying insufficient lubrication or contamination.

Prevent unexpected downtime: Avoid unexpected equipment shutdowns by scheduling maintenance based on particle analysis results.

For those using high-performance bearings in demanding environments, CNEPEN Bearings offers a variety of solutions that can enhance bearing lifespan and operational efficiency.

Conclusion

Analyzing wear particles in sliding bearings is an invaluable tool for maintaining equipment and diagnosing potential issues before they cause serious damage. With the right tools and techniques, maintenance teams can detect early signs of wear, pinpoint the cause, and optimize the performance of the bearings. This proactive approach not only extends the lifespan of bearings but also helps prevent costly downtime and repairs.

For more information on our advanced sliding https://www.cnepen.combearing solutions, visit our Products Page or contact us today.

FAQs

In plain bearings, what ranges of particle sizes show normal and abnormal wear?

Normal operation makes particles that are usually less than 10 microns across. Particles larger than 20 microns usually mean that things are wearing out faster or that problems are starting to form. But each kind of bearing, each set of operating conditions, and each piece of equipment has its own thresholds.

How often should particle analysis be done on equipment that is very important?

How often you have to analyze depends on how important the equipment is and how it is working, but sampling once a month while it's working normally gives enough data to see how it's changing over time. Automated systems may need to keep an eye on applications with a lot of risk every week or even all the time.

Can wear particle analysis tell the difference between bearing wear and contamination from outside sources?

Yes, particle composition analysis can tell the difference between bearing material debris and outside contamination. Particles that are bearing usually match the materials of the substrate, but impurities have different elemental signatures or morphological features.

Partner with Epen for Advanced Sliding Bearings Solutions

Jiashan Epen Bearing Co., Ltd. makes high-performance sliding bearings that are designed for condition monitoring applications. Our wide range of products includes metal-plastic composite bearings, bimetal bearings, and specialized plain bearings that are made to work best with wear particle analysis. With cutting-edge materials and exact manufacturing skills, we make bearings that help predictive maintenance programs work well in the automotive, metallurgy, engineering machinery, and construction equipment industries.

Along with condition monitoring consultation and tailored answers for certain analytical needs, we also have a lot of experience in manufacturing. We know how important it is for bearings to work well in tough industrial settings, and we offer full support from the moment of purchase throughout the product's life. Our team offers options that make your equipment more reliable and support advanced diagnostic features. We can help whether you need standard catalog sizes or custom-designed bearings.

Learn how our precision-engineered sliding bearings can make your equipment more reliable and improve the effectiveness of your condition monitoring. To talk about your exact needs and look at all the sliding bearings we have for sale, please email us at epen@cnepen.cn.

References

Roylance, B.J. & Hunt, T.M. (1999). "Wear Debris Analysis: Ferrography and Oil Analysis Techniques for Machine Condition Monitoring." Coxmoor Publishing Company.

Anderson, D.P. (2005). "Wear Particle Atlas: A Guide to Particle Identification for Predictive Maintenance." Naval Air Systems Command, Patuxent River, Maryland.

Seifert, W.W. & Westcott, V.C. (2001). "A Method for the Study of Wear Particles in Lubricating Oil." Wear, Volume 21, Issue 1, Pages 27-42.

Hunt, T.M. (1993). "Handbook of Wear Debris Analysis and Particle Detection in Liquids." Elsevier Applied Science.

Peng, Z. & Kirk, T.B. (1997). "Computer Image Analysis of Wear Particles in Three Dimensions for Machine Condition Assessment." Wear, Volume 203-204, Pages 616-624.

Stachowiak, G.W. & Batchelor, A.W. (2014). "Engineering Tribology: Fourth Edition - Chapter 18: Wear Debris Analysis." Butterworth-Heinemann.