Abnormal noise in sliding bearings is often an early warning signal of failure, especially in applications involving oscillatory motion, linear motion, heavy loads, or harsh environments. Ignoring these sounds can quickly lead to accelerated wear, unplanned downtime, and costly equipment damage.

For OEMs, maintenance engineers, and industrial buyers worldwide, understanding the root causes of abnormal bearing noise—and how to prevent them—is essential for improving reliability and extending service life.

This article outlines the seven most common causes of abnormal noise in sliding bearings, along with practical countermeasures and proven engineering solutions.

What Is “Abnormal Noise"in Sliding Bearings?

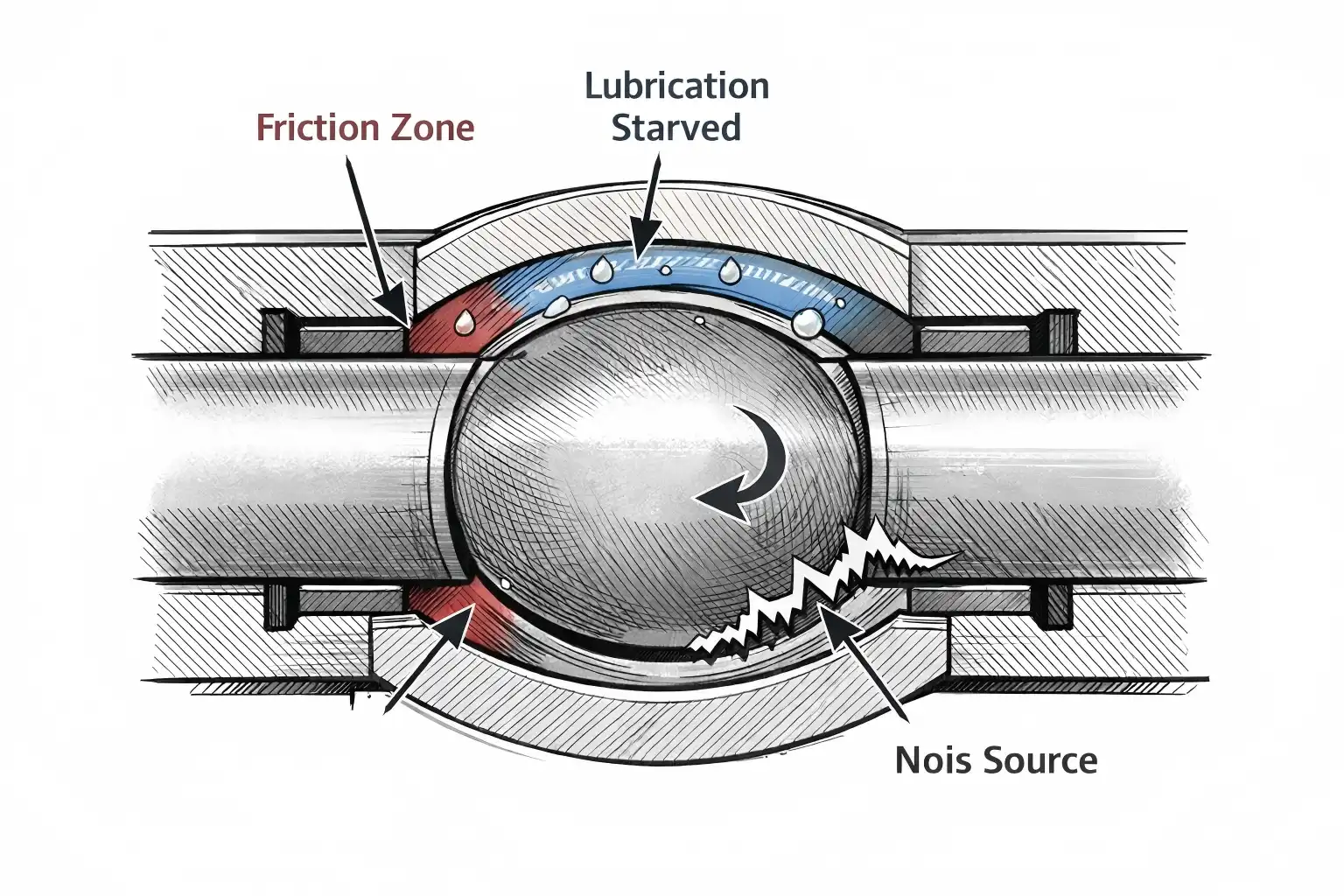

Unlike rolling bearings, sliding bearings typically operate quietly under correct conditions. When noise appears—such as squealing, grinding, knocking, or vibration—it usually indicates:

Boundary or dry friction

Surface damage or material fatigue

Installation or design issues

Environmental contamination

High-quality sliding bearings, such as those engineered by CNEPEN, are designed to minimize these risks even in demanding applications.

🔗 Explore CNEPEN sliding bearing solutions:

https://www.cnepen.com/sliding-bearings

Cause 1: Insufficient or Incorrect Lubrication

Symptoms

High-pitched squealing

Dry friction noise during start-stop cycles

Temperature rise

Root Cause

Inadequate lubrication prevents the formation of a stable friction film, forcing metal-to-metal contact.

Countermeasures

Select self-lubricating or maintenance-free materials

Match lubricant type to load, speed, and temperature

Avoid over- or under-lubrication

🔗 Self-lubricating sliding bearings:

https://www.cnepen.com/self-lubricating-bearings

Cause 2: Material Mismatch or Poor Bearing Selection

Symptoms

Persistent noise from early operation

Rapid wear despite proper lubrication

Root Cause

Bearing materials not suited for the operating conditions (load, speed, temperature, or motion type).

Countermeasures

Use application-specific bearing materials

Choose composite or bi-metallic bushings for heavy loads

Consider high-temperature or corrosion-resistant designs

🔗 Engineered bearing materials by CNEPEN:

https://www.cnepen.com/bearing-materials

Cause 3: Misalignment or Improper Installation

Symptoms

Knocking or cyclic noise

Uneven wear patterns

Increased vibration

Root Cause

Shaft misalignment or incorrect press-fit leads to localized stress and uneven contact.

Countermeasures

Ensure proper housing tolerances

Use bearing designs that tolerate misalignment

Follow recommended installation procedures

🔗 Technical support & custom bearing solutions:

https://www.cnepen.com/custom-bushings

Cause 4: Contamination by Dust, Debris, or Moisture

Symptoms

Grinding or scratching noise

Sudden increase in wear

Lubricant degradation

Root Cause

Foreign particles disrupt the sliding interface and damage the bearing surface.

Countermeasures

Use sealed or maintenance-free sliding bearings

Select materials resistant to abrasion

Improve environmental sealing

Cause 5: Excessive Load or Shock Loading

Symptoms

Deep knocking sounds

Deformation-related noise

Premature bearing failure

Root Cause

Operating loads exceed bearing design limits, often combined with impact or shock forces.

Countermeasures

Increase bearing contact area

Use reinforced or bi-metallic bushings

Re-evaluate load distribution in the design stage

🔗 High-load bi-metallic bushings:

https://www.cnepen.com/bi-metallic-bushings

Cause 6: High-Temperature Operation

Symptoms

Noise increase after warm-up

Material softening or deformation

Lubricant breakdown sounds

Root Cause

Elevated temperatures degrade polymers, lubricants, or surface layers.

Countermeasures

Select high-temperature sliding bearing materials

Avoid standard polymers in thermal-critical zones

Use dry-running or solid-lubricant designs

Cause 7: Fatigue Wear and Surface Damage

Symptoms

Intermittent clicking or knocking

Progressive noise increase over time

Visible surface flaking or scoring

Root Cause

Repeated cyclic stress leads to fatigue damage at the sliding interface.

Countermeasures

Optimize bearing material and surface structure

Reduce peak stress through better load distribution

Replace bearings before end-of-life failure

Why Choosing the Right Bearing Supplier Matters

Abnormal noise is rarely caused by a single factor—it is usually the result of material selection, design, installation, and operating conditions combined.

Working with an experienced manufacturer like CNEPEN provides:

Application-specific material recommendations

Proven designs for oscillatory and linear motion

Solutions for high temperature and harsh environments

Stable global supply for OEMs and distributors

🔗 Contact CNEPEN for technical consultation:

https://www.cnepen.com/contact-us

Conclusion:Silence Is a Sign of Reliability

In sliding bearings, noise is never “normal.” It is an early indicator of friction imbalance, material failure, or environmental stress.

By understanding the seven key causes of abnormal noise and implementing the right countermeasures—especially through proper bearing selection—you can dramatically improve equipment reliability, reduce downtime, and lower total cost of ownership.

For quiet, durable, and engineered sliding bearing solutions, trust CNEPEN to support your applications worldwide.

Partner with Epen for Superior Sliding Bearing Solutions

Jiashan Epen Bearing Co., Ltd. makes high-quality plain bearings and wear plates that are designed to keep noise down and performance up in difficult industrial settings. Our wide range of products includes bimetal bearings, metal-plastic composite bearings, and single-metal series parts. These are used in cars, metalworking, engineering machinery, and construction equipment all over the world.

Noise control is very important for industrial operations, and as a sliding bearings manufacturer that people trust, we know this. To help you choose the best bearing parts for your needs, our knowledgeable engineering team offers technical advice, tailored solutions, and ongoing support. Epen offers low prices without sacrificing quality, whether you need standard catalog sizes or custom designs.

Do you want to get rid of bearing noise problems and make your equipment more reliable? To talk about your needs and find out how Epen's advanced sliding bearing solutions can help your business, get in touch with our technical experts today. For professional help and good prices tailored to your business needs, email us at epen@cnepen.cn.

References

Johnson, M.R. "Tribological Analysis of Plain Bearing Noise Generation Mechanisms." Journal of Industrial Tribology, Vol. 45, No. 3, 2023, pp. 127-142.

Chen, L. and Williams, D.K. "Lubrication Strategies for Noise Reduction in Heavy Machinery Sliding Bearings." International Conference on Mechanical Engineering, 2023, pp. 234-248.

Thompson, A.B. "Misalignment Effects on Acoustic Emissions in Industrial Plain Bearings." Mechanical Systems and Signal Processing, Vol. 78, 2024, pp. 89-104.

Rodriguez, C.M. "Contamination Impact Assessment on Sliding Bearing Performance and Noise Generation." Wear Analysis Quarterly, Vol. 29, No. 2, 2023, pp. 156-171.

Smith, R.J. and Kumar, S. "Thermal Management Techniques for Noise Control in Construction Equipment Bearings." Heavy Machinery Engineering Review, Vol. 31, 2024, pp. 67-82.

Anderson, P.L. "Material Selection Criteria for Low-Noise Plain Bearing Applications in Mining Equipment." Materials and Design for Industrial Applications, Vol. 52, 2023, pp. 203-218.